- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1 Author: 立向包装 Publish Time: 2025-03-12 Origin: 奥立包装

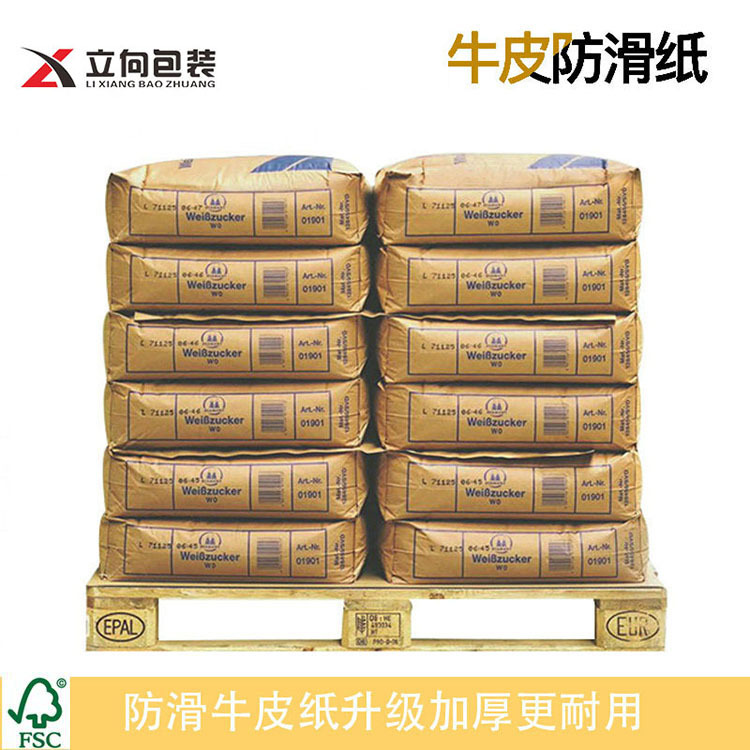

The Capability of Using Slip Sheets and Pallets: Enhancing Efficiency in Modern Logistics

In the fast-paced world of logistics and supply chain management, the choice between slip sheets and pallets can significantly impact operational efficiency, cost savings, and sustainability. Both methods have unique advantages and capabilities, and understanding their strengths is essential for optimizing logistics processes. This article explores the capabilities of using slip sheets and pallets, their applications, and how businesses can leverage them to improve their operations.

Slip Sheets:

Thin, flat sheets made of paperboard, plastic, or corrugated fiberboard, used as an alternative to traditional pallets. They require a push-pull attachment on forklifts for handling.

Pallets:

Rigid platforms, typically made of wood, plastic, or metal, used to stack, store, and transport goods. They are compatible with standard forklifts and pallet jacks.

Space Efficiency:

Slip sheets are ultra-thin, allowing more goods to be loaded into shipping containers or trucks, maximizing space utilization.

Cost Savings:

They are lighter and cheaper than pallets, reducing transportation costs and material expenses.

Sustainability:

Slip sheets are often made from recyclable materials, aligning with eco-friendly initiatives.

Automation Compatibility:

Ideal for automated warehouses, as they can be easily handled by robotic systems.

Customization:

Can be tailored to fit specific product dimensions, reducing the risk of damage during transit.

Durability:

Pallets are robust and can handle heavy loads, making them suitable for a wide range of industries.

Ease of Handling:

Compatible with standard forklifts and pallet jacks, requiring no specialized equipment.

Versatility:

Available in various materials (wood, plastic, metal) and sizes, catering to different needs.

Global Standardization:

Pallets are widely accepted and used in international trade, ensuring seamless logistics.

Reusability:

Many pallets are designed for multiple uses, reducing long-term costs.

Slip Sheets:

Ideal for lightweight, uniform products like packaged foods, beverages, and consumer goods.

Commonly used in industries with high-volume, low-weight shipments, such as retail and e-commerce.

Suitable for automated warehouses and distribution centers.

Pallets:

Perfect for heavy or irregularly shaped items, such as machinery, construction materials, and bulk goods.

Widely used in manufacturing, agriculture, and pharmaceuticals.

Essential for international shipping due to their standardized dimensions.

Product Characteristics:

Use slip sheets for lightweight, uniform products and pallets for heavy or irregular items.

Logistics Infrastructure:

Slip sheets require specialized equipment (push-pull attachments), while pallets are compatible with standard forklifts.

Cost Considerations:

Slip sheets are cheaper and lighter, but pallets offer greater durability and reusability.

Sustainability Goals:

Both options can be eco-friendly, but slip sheets often have a lower environmental footprint due to their lightweight design.

In some cases, businesses can benefit from using both slip sheets and pallets in their operations. For example:

Use slip sheets for high-volume, lightweight shipments within a warehouse.

Switch to pallets for international shipping or heavy-duty applications.

Implement hybrid systems where slip sheets are used for storage and pallets for transportation.

Automation and Robotics:

Slip sheets are becoming increasingly popular in automated warehouses, while pallets are being adapted for robotic handling.

Sustainable Materials:

Both slip sheets and pallets are evolving to incorporate biodegradable and recyclable materials.

Smart Logistics:

Integration of IoT and RFID technology to track and manage slip sheets and pallets in real-time.

The capability of using slip sheets and pallets offers businesses a range of options to optimize their logistics operations. While slip sheets excel in space efficiency, cost savings, and automation compatibility, pallets provide durability, versatility, and global standardization. By understanding the strengths of each method and aligning them with specific needs, businesses can enhance efficiency, reduce costs, and contribute to a more sustainable supply chain.

Whether you choose slip sheets, pallets, or a combination of both, the key is to evaluate your product characteristics, logistics infrastructure, and operational goals. Embracing the right solution will not only streamline your processes but also position your business for success in the competitive world of modern logistics.