- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: lixiang pack Publish Time: 2025-12-19 Origin: aolipack

In modern supply chains, companies constantly seek ways to reduce costs, improve efficiency, and enhance sustainability. The choice between slip sheets and pallets significantly impacts these goals. This comprehensive comparison will help you determine which solution best fits your operations.

| Feature | Slip Sheets | Pallets |

|---|---|---|

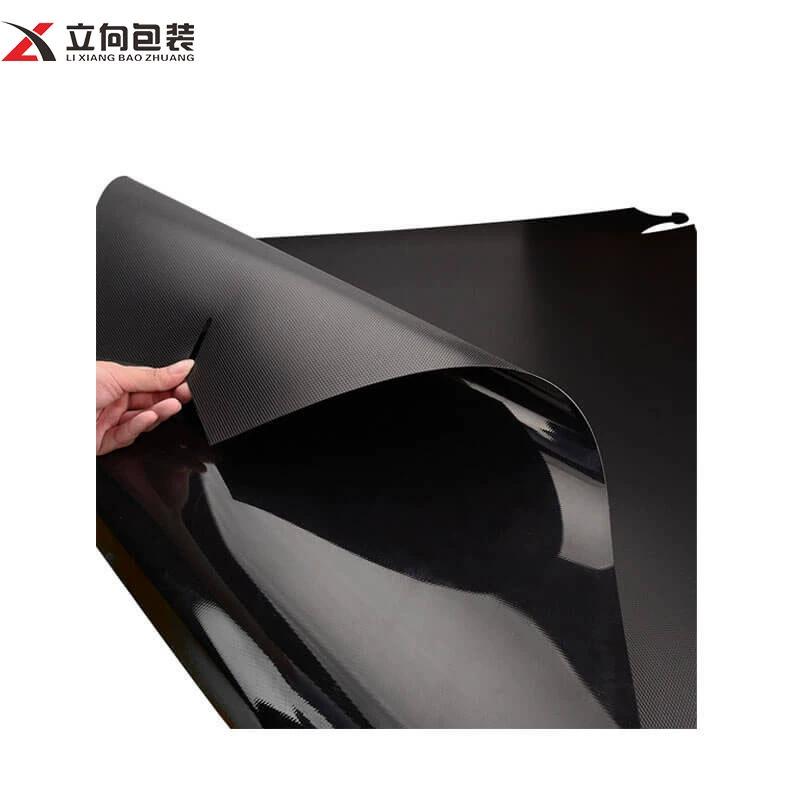

| Material | Plastic (HDPE/PP) or fiberboard | Wood, plastic, or metal |

| Weight | 1-3 kg | 15-30 kg (wood), 10-20 kg (plastic) |

| Thickness | 0.5-3 mm | 100-150 mm |

| Cost per Unit | 4−4−15 | 15−15−50 (wood), 50−50−150 (plastic) |

| Lifespan | 50-100 uses | 10-20 uses (wood), 100+ (plastic) |

| Space Efficiency | 100% stackable | 15-20% space loss |

| Forklift Requirements | Needs push-pull attachment | Standard forks |

✔ Lower upfront cost (4−4−15 vs. 15−15−150)

✔ Reduced shipping costs (lighter weight = lower freight charges)

✔ No pallet disposal fees

✔ No special equipment needed (standard forklifts work)

✔ Better for heavy loads (no weight limitations)

Winner: Slip sheets for high-volume shipping, pallets for heavy single-item loads

Slip sheets save 15-20% space vs. pallets

No wasted height (slip sheets are <3mm thick vs. 150mm pallets)

Nestable when empty (vs. bulky pallet storage)

Example:

A 40ft container fits:

24 pallets (standard loading)

30+ slip sheet loads (optimized space usage)

Winner: Slip sheets for space-sensitive shipments

50-100 uses (HDPE/PP)

Single-use (fiberboard option)

Vulnerable to tears if overloaded

10-20 uses (wood)

100+ uses (plastic)

Withstands rough handling better

Winner: Plastic pallets for long-term heavy use, slip sheets for controlled environments

✅ Air freight (ultra-lightweight)

✅ Food/pharma (FDA-compliant non-porous surfaces)

✅ E-commerce (space optimization)

✅ Export packaging (maximize container loads)

✅ Construction materials (extreme weights)

✅ Uneven loads (better stability)

✅ Outdoor storage (weather resistance)

| Factor | Slip Sheets | Pallets |

|---|---|---|

| Material | Recyclable plastics/fiberboard | Wood (biodegradable but treated) |

| Carbon Footprint | Lower (lighter shipments) | Higher |

| End-of-Life | 100% recyclable | Wood often landfilled |

Winner: Slip sheets for eco-conscious operations

Slip sheets require:

Push-pull forklift attachment (3,000−3,000−8,000)

Staff training

Pallets require:

No equipment changes

Higher ongoing purchase costs

Break-even point: ~6-12 months for slip sheet conversion

"After analyzing 200+ client cases, we recommend slip sheets for businesses shipping high volumes of uniform packages, especially in food, pharma, and e-commerce. Pallets remain superior for heavy, irregular loads and outdoor applications."

— John Mercer, Supply Chain Consultant

For high-quality slip sheets:

Shanghai Livon Packaging

+86 21 5836 1988

www.livonpackaging.com

For durable pallets:

Local wood/plastic pallet manufacturers

Switch to slip sheets if:

✔ You ship high volumes of uniform boxes

✔ Container space optimization is critical

✔ You want to reduce shipping costs

Stick with pallets if:

✔ You handle heavy, irregular loads

✔ Outdoor storage is required

✔ You lack specialized forklift equipment

Pro Tip: Many businesses use both solutions - slip sheets for export shipments and pallets for domestic warehouse operations.